Sales Tel

+86-19879958318

|

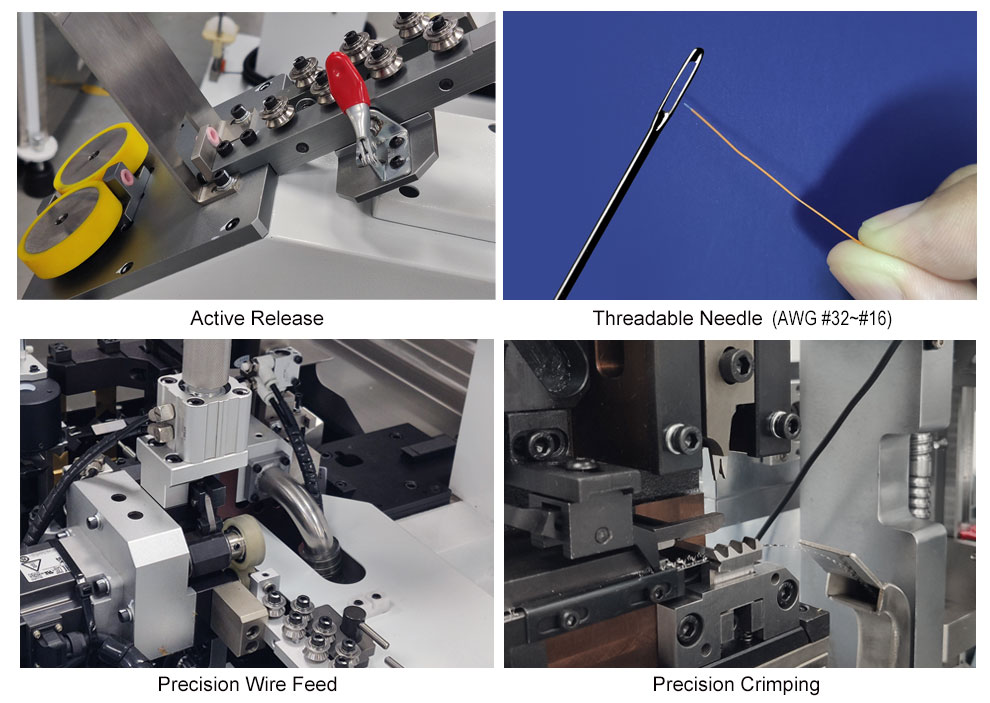

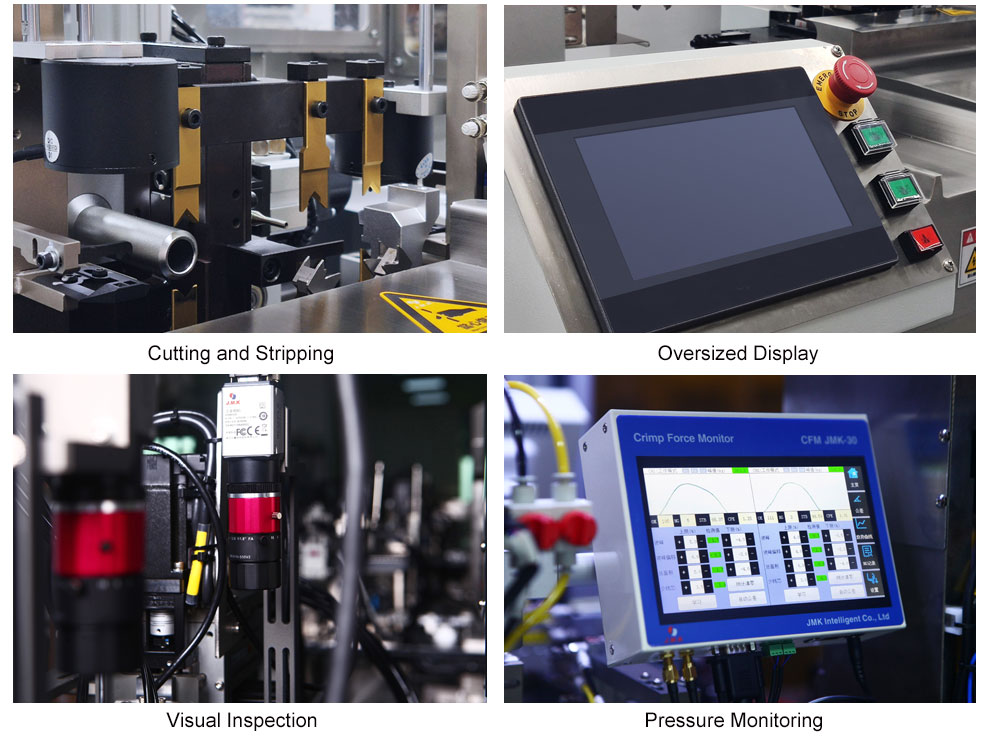

Wire Cutting and Stripping /Dual Head Crimping /Pressure Monitoring /Visual Inspection

Product Features:

This high-precision machine uses servo motors and ball screw drives to ensure accurate wire feeding, stripping, and crimping. It handles short ultra-fine wires from AWG #32 to AWG #16 (0.13-1.25 mm) and can reach speeds of up to 3,500 pieces per hour.

1.Optional crimp force monitoring

2.Optional visual inspection system

3.Automatic sorting of defective products

4.Full-process quality control

Reliable, efficient, and ideal for precision wire harness production.

Technical Parameters:

| Model |

Automatic Double-end Terminal Crimping Machine |

| Feeding speed |

Approx. 3500 pcs/hour (L=100mm) |

|

Cutting length |

30 ~9999mm |

|

Cutting precision |

(0.2+0.00005×L) mm |

|

Stripping length |

0~15mm |

|

Crimp force |

2T |

|

Control method |

Inverter drive, AC motor |

|

Display language |

Chinese/English |

|

voltage,air supply |

220V 50/60HZ, 0.5Mpa 150(ANR)/min |

|

Size |

L1100mm x W920mm x H1600mm |

|

Weight |

525KG |

|

Adaptive line species |

AV, AVS, AVSS, CAVUS, KVKIV, UL |

|

Size of wire laying frame |

L930 x W500 x H1260 mm |