Sales Tel

+86-18928379199

|  |  |  |

Cutting stripping/Single/double end crimping/Waterproof plug threading/Wire conduit/Heat shrink tube threading/Flexible configuration of workstations

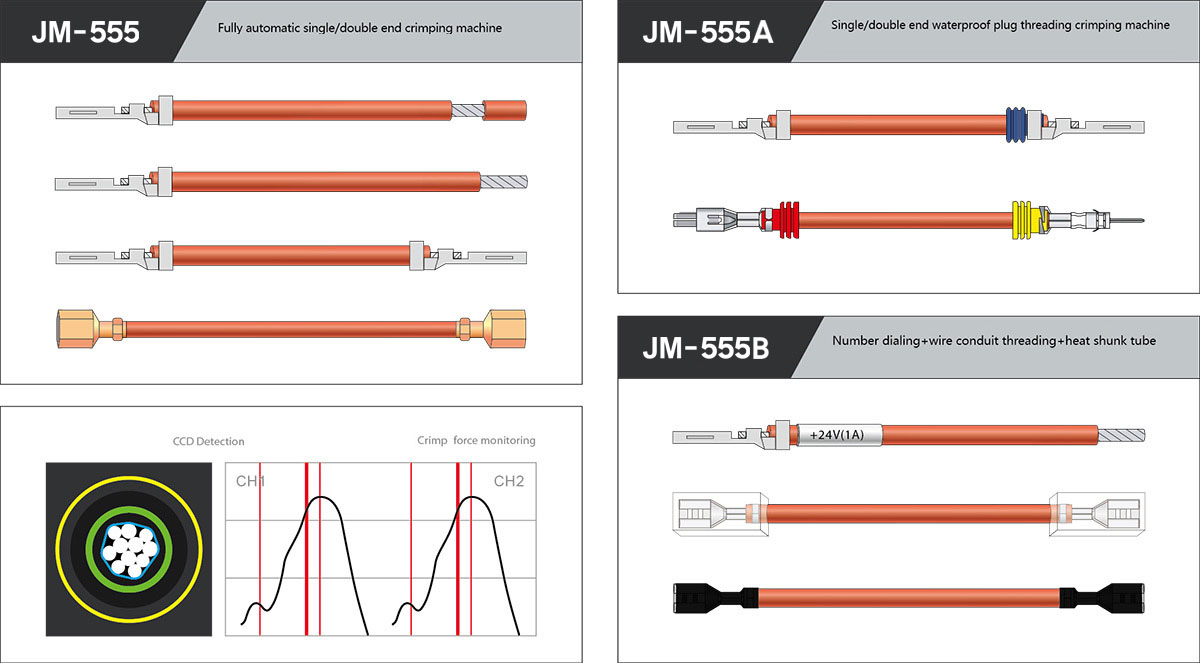

JM-555 automatic wire crimping machine are able to do fixed-length cable/wire cutting, single/double end half-stripping or full-stripping, single/double end crimping, waterproof plug threading, number dialing, and Wire Conduit/heat shrink tube threading. And all processes can be completed synchronously.

Product Feature:

1.International-grade design with a compact and streamlined structure;

2.Equipped with a flexible wire feeding system that protects the wire surface while ensuring high wire length accuracy;

3.Utilizes a servo-driven crimping system to guarantee stable and consistent crimping precision;

4.User-friendly PC interface with graphical display for intuitive and simplified operation;

5.Built-in pressure management system enables real-time monitoring, automatic defect detection, and removal;

6.Supports customized processing for FAKRA wire harnesses and ultra-short new energy harnesses;

|

Model |

JM-555-----JM-555A-----JM-555B JM-555 Automatic Wire Crimping Machine(Cutting Stripping Crimping Seal Insertion Heat Shrink Tube Threading ) |

|

Power supply |

AC380V/50-60Hz |

|

Capacity |

1000~5200pcs/H(shortest cut wire) |

| Air supply |

0.5-0.7MPa |

|

Air consumption |

3m/h |

| Cutting length | 50-9999mm |

| Cutting precision | ≤1000mm,±1mm,21000mm,((1000mm+0.2%xL) |

| Stripping length | 0.1-16mm |

| Wire range | 0.13-6.0mm2(26-10 AWG) |

| Feeding speed | 8-12m/s(Max) |

|

Crimping force |

20KN (tonnage can be customized) |

|

Crimp travel |

30mm(40mm Optional) |

|

Ambient temperature |

0~40℃ |

| Size |

L3720xW1450xH2010mm(protection quantity lifting height about 2850mm) |

|

Weight |

About 1000kg |

|

Optional |

Wire seal station; Wire conduit station; Visual module of crimper; Puller; Magnifying glass; Electronic micrometer; Safety cover |

JM-555 has a modular design, so it can be customized or add different functions according to the actual needs of customers, without having to equip other machines separately. In order to adapt to the larger market demand, it has been continuously improved at the time of research and development for many years, so it fully has the corresponding independent system, and can be added and deleted according to the requirements. In this way, it can not only achieve comprehensive functions, but also meet customized requirements, then improve production efficiency and save users cost of purchasing machines at the same time.

Wire harness case:

Automatic wire crimping machine with integrated insulation modules are engineered for high-precision crimping of various terminals.

They support both single- and double-sided crimping for single-core and multi-core cables—including round, flat, and ribbon types.

These presses are known for their outstanding precision, reliability, and efficiency.

A wide range of optional modules is available to enhance functionality, including Crimp Force Monitoring (CFM), tinning, twisting, labeling, heat shrink tubing application, and automated feeding systems.