Sales Tel

+86-18928379199

|  |  |

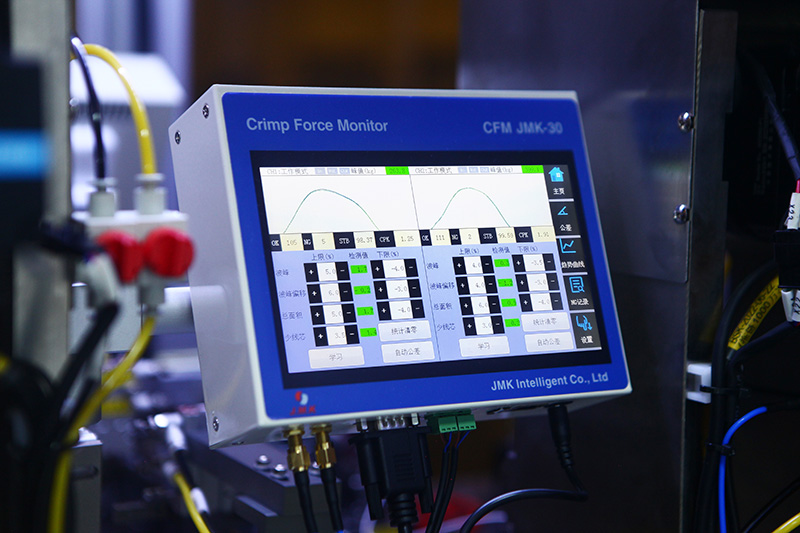

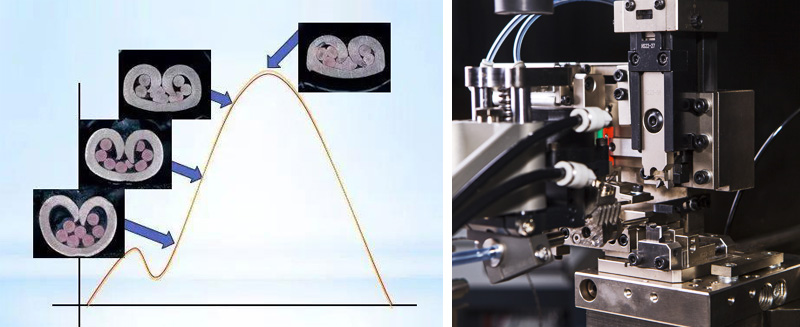

JMK intelligent (single / double) channel pressure monitoring system adopts waveform reading method which is not easily affected by mechanical vibration. Get stable waveform, analyze crimping effect with curve, trigger alarm when crimping is bad. It can detect defects with high precision and reduce misjudgment at the same time.

Product Feature:

1. It can effectively detect the defects in the terminal crimping process, including rubber bite crimping position, broken copper wire crimping size change, terminal deformation, die damage and so on.

2. Can be used in a variety of automatic or semi-automatic crimping machines, using simple, stupid operation.

3. With the upper software, the functions such as data query and data export can be realized.

4. Advanced pressure curve algorithm to provide high-precision defect detection and reduce false positives.

5. Multi-learning template switching function, you can achieve a variety of wire rod to the same terminal. Each kind of wire has its own learning curve.

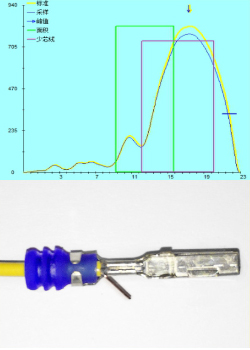

Example of a poorly crimped waveform:

| Core Wire Warping | Wire Skin Bite In |

Shallow Hit |

Core breakage |

|

|

|

|

| The pressure waveform of the alarm has a tendency to decrease in the whole area of the waveform, but the waveform does not have a serious tilt; the same waveform occurs when the core wire is broken. | The insulation material extends more into the crimped section and is crimped with the core wire, thus causing the core wire to break; thus a sharp decrease in pressure is clearly observed before it reaches its peak. | The degree of shallow beating is expressed in terms of the distance between the front of the core wire and the flare of the terminal crimp, and although the waveforms of the pressures are very similar, the waveforms are both reduced overall, with the result that they both cause the tolerance of the fluctuations to become negative. | During the crimping process, the core wire breaks due to the knife value or the cutter, and the crimping waveform will clearly show a downward trend before reaching the peak value. |