Sales Tel

+86-18928379199

2025 Munich Shanghai Electronics Manufacturing Equipment Exhibition JMK's various wire harness automation equipment re-released!

★ Exhibition time: March 26-28, 2025

★ Exhibition location: Shanghai New International Expo Center

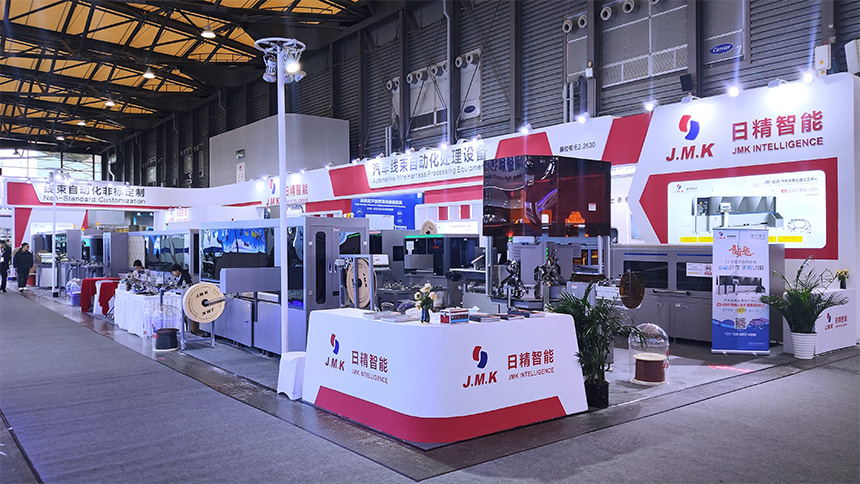

★ JMK: Booth No. - E2 Hall 2630#

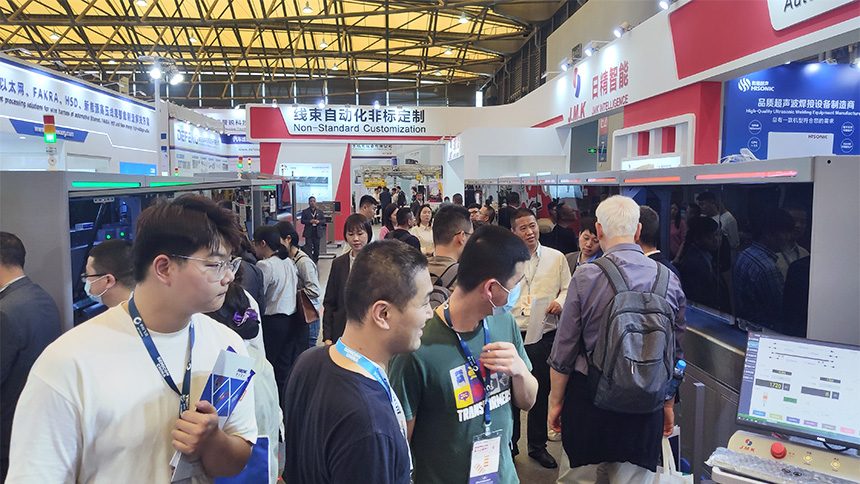

Munich Shanghai Electronics Production Equipment Exhibition is the electronic intelligent manufacturing industry is crucial to the display of the exchange platform, March 26-28, 2025, a three-day 2025 Munich Shanghai Electronics Production Equipment Exhibition concluded successfully, attracting a total of visitors JMK Booth No. 2630, Hall E2, made a grand appearance with a variety of wire harness automation equipment. The scale of this year's Electronic Manufacturing Equipment Show (EMEA) in Munich continues to expand, bringing together 1,101 exhibitors and showcasing new products and cutting-edge technologies for intelligent electronics manufacturing in nearly 100,000 square meters of exhibition halls. These include electronic and chemical materials, dispensing and bonding technology, electronic assembly automation, test and measurement and quality assurance, electronics manufacturing services, surface mount technology, wire harness processing and connector manufacturing, component manufacturing, motion control and drive technology, industrial sensors, robotics and intelligent warehousing. Visitors will not only be able to experience the new technologies and achievements up close, but also have the opportunity to engage in in-depth dialog with industry experts and seek common development paths for the industry.

Exhibitors

JMK specializes in wire harness automation processing equipment solutions and R & D and manufacturing, products include automated automation processing equipment for automotive wire harnesses, FAKRA Ethernet automated production line, new energy high-voltage wire harness production line, automatic multi-station terminal crimping machine, automatic terminal insertion machine, etc., and to provide non-standard customization, pneumatic cassette molds, CCD visual inspection, pressure monitoring system, and other various processing modules and auxiliary equipment. JMK has an excellent R&D team.

JMK has excellent R & D team, management team and perfect sales and service system, the company has accumulated nearly 20 years of technical experience in the industry, and its comprehensive strength ranks the forefront of the country. At present, it has established industrial parks and sales and service outlets in Shenzhen, Suzhou, Huizhou and Hubei. The business covers all over the country and is exported to overseas regions. We have established cooperation with many large wiring harness enterprises at home and abroad, such as BYD, Tyco, Amphenol, etc. The equipment has been highly recognized by customers and production verification. The company has won a number of invention and utility model patents, has passed ISO9001, Dun & Bradstreet registration certification, access to national high-tech enterprises, specializing in new, national quality and service integrity AAA enterprise certification and many other honors.

JMK Automotive Wire Harness Automated Processing Equipment

JMK released a variety of wire harness automation equipment, covering new energy, automotive, electric power, photovoltaic energy storage, home appliances and other industries, including low-voltage and high-voltage wire harness automation production line, automatic multi-station terminal crimping machine, shell insertion machine, FAKRA and other wiring harness automation processing equipment.

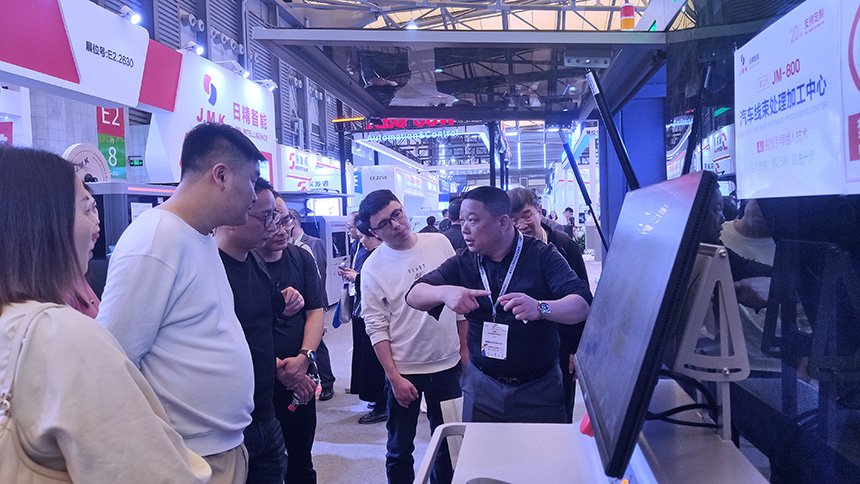

JMK general manager, Li Meng, introduced the newly developed third-generation automated automotive wiring harness processing center to the visitors, applying the AI vision-guided insertion technology, which automatically corrects the terminal insertion angle and spacing through AI intelligent algorithms and optical measurement system, so that the terminals can be accurately positioned and inserted into the connector, and conducts full measurement and control of insertion and pull-back forces throughout the entire insertion process to ensure that the terminal insertion is stable and in line with the predetermined quality standards. The insertion force and pull-back force are measured and controlled throughout the insertion process to ensure that the terminals are inserted securely and in accordance with predetermined quality standards.

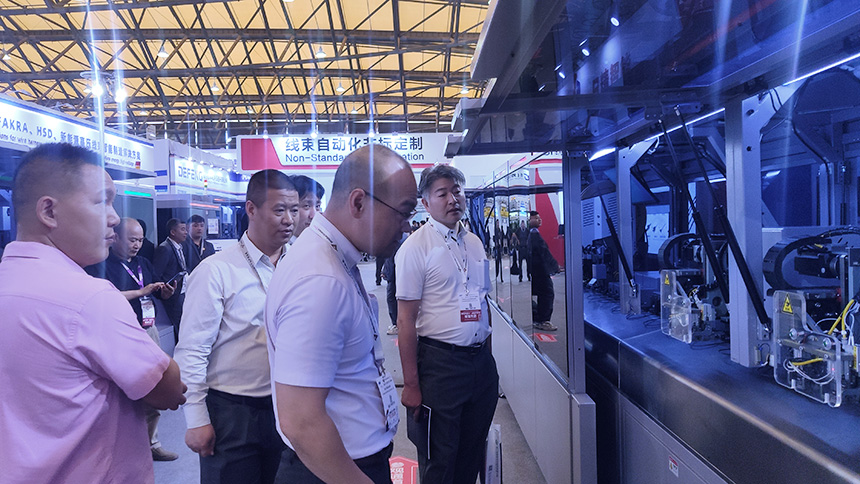

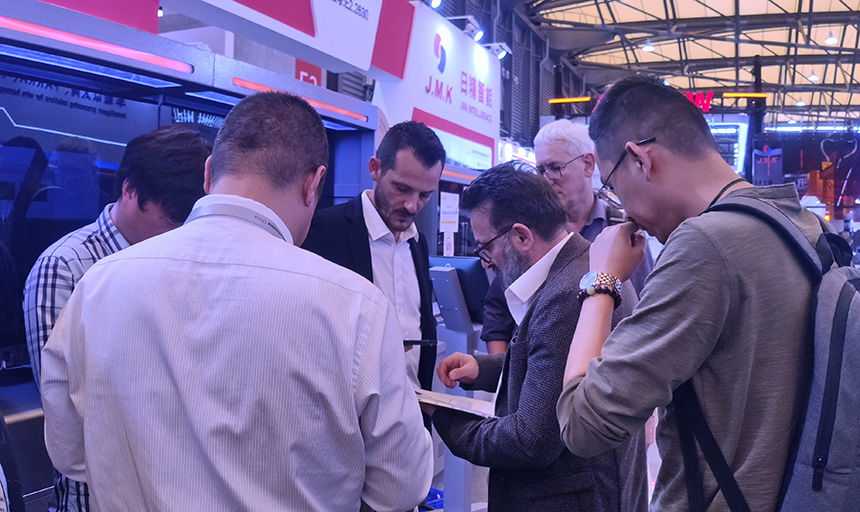

The technology and products, in the field of wire harness automation in the country and even the world can be said to be second to none, the scene was crowded, visitors with enthusiasm for cutting-edge technology, watching the equipment demonstration and consultation with interest, can not hold back the curiosity of the heart, some people are eager to explore the production efficiency of the equipment; some people carefully calculated, focusing on the procurement cost, and strive to maximize the benefits of the introduction of advanced technology at the same time. The staff handed out brochures, while enthusiastically recommending the equipment to the guests for technical exchanges, the scene will be the charm of the top achievements in wire harness automation revealed.